Services

We offer a variety of services, including non-destructive testing and site surveying.

With many lighting columns in the UK coming to the end of their predicted lifespans, it has never been more important to have a sound knowledge of your existing assets. We offer a mini-test or a full test, both of which will give you valuable insight into the conditions of your assets.

- Visual inspection, which is to be carried out internally and externally, where accessible. This is to check for any signs of corrosion, impact damage, holes, to see if the column is leaning and any other noticeable defects.

- Column data and attributes, including; the material type of the column, is the column full of water at the base or is it well-drained? External influences and conditions, does the column have existing attachments? Is there any protective treatment present?

- Corrosion detection through the Eddy Current Test, can reveal faults at ground level which are difficult to monitor without excavation.

- A full suite of photographs, including endoscope inspection internally when required.

- Coating thickness.

- Ultrasonic testing of thickness, in accordance with GN22.

- Column measurements – door, shaft and base measurements which are then used during the reverse engineering stage.

- Reverse engineering using design software, checking the column and any attachments in accordance with EN40

- Ultrasonic Sectional Thickness Analysis on Steel and Aluminium Columns.

- GN22 Compliant.

- HERS, HEA and G39 Accredited.

Our years of experience and vast expertise in the loading and deflection of lighting columns means we can produce results which you can trust. Data collected first hand from onsite visits can be fed into our complex structural analysis software, where we are able to produce EN40 design checks on the columns. Whether you’re looking to add new elements to an existing project, or simply review your existing assets, Fabrikat can give you confidence that your columns are loaded safely.

- Analysis of current column loading.

- Analysis of the effect of additional attachments.

- Advice on specification changes to bring the column within safe loading.

Alongside our extensive manufacturing capabilities, we also offer on-site surveys as a service. We use the latest GPS technology in order to provide surveys which will cover large areas, quickly.

Due to the restrictions of GPS, we also carry traditional and laser measuring equipment to ensure that all areas can be surveyed, regardless of any near buildings, trees or other coverages which may obscure GPS data.

These surveys can be provided to fit most CAD formats. We use these surveys ourselves to aid in the design and manufacture of bespoke, made-to-measure products.

Please get in touch below for a quote.

- GPS Measuring

- Traditional Measuring

- Laser Measuring

- In-depth surveys for CAD Design

- One-off prototyping at a rapid pace.

- A choice of ABS and PLA printing materials.

- 3D visualisation of the product concepts.

3D Scanning

Using the latest in 3D scanning technology we can quickly replicate and convert complex real word forms into high fidelity 3D models. This allows us to edit, improve and adapt designs through a completely new medium.

Since 3D scanning is so versatile there is virtually no limit to the shape or scale of the object.

- Real time 3D visualization

- High fidelity output file

- Rapid results

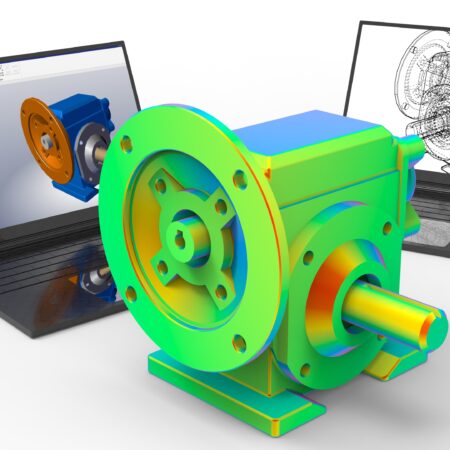

The use of software can now bypass the countless iterations of physical modelling. We can apply FEA techniques to your individual problem, to provide a simulation of how a component or product may perform under strain. Solid CAD models can be meshed and loaded to give insight into part longevity and effectiveness.

- Individualised approach

- Insight into longevity and effectiveness of parts

Get In Touch, Discuss Your Project

Do you have any questions about our products or want to discuss your next project? Get in touch via any of the methods below...